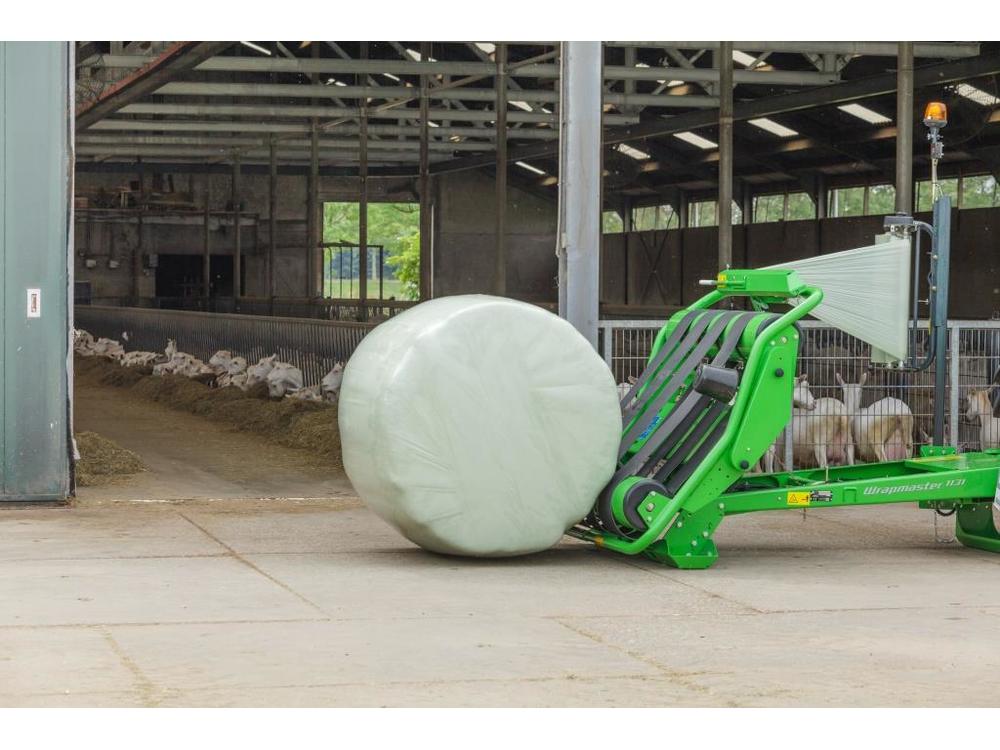

Bale Wrappers

BALES WRAPPED TO PERFECTION

Crucial part of the silage making process is wrapping the bale for storage. By wrapping the bale nutrient loss is prevented and as a result maximum nutrient value is secured for your cattle after storage time. DEUTZ-FAHR offers the most complete and versatile range of individual wrappers available for the market. DEUTZ-FAHR wrappers are fast, efficient and above all reliable. Starting with stationary round bale wrappers up to trailed large square bale wrappers used by contractors. Thanks to several unique features DEUTZ-FAHR wrappers make a real difference in storing a quality crop. Low-profile chassis design: DEUTZ-FAHR mounted turntable bale wrappers feature an exclusive low profile frame which ensures absolute stability when loading, wrapping and unloading bales. The position of the rear axle makes it possible for the frame to be closer to the ground, eliminating the need for an (active) fall damper. There is constant weight transfer to the tractor, that prevents up-and down movements of the drawbar and prevents tractor wheel slippage when driving uphill with a bale on the table or loading arm. The bale can be dropped on the go for maximum output! Round turntable: The DEUTZ-FAHR round bale turntable wrappers are equipped with two rollers and four wide-spaced belts. This design provides a deep and stable cradle for the bale on the wrapping turntable. The two large bale support rollers provide more stability and guidance. The four wide-spaced belts provide maximum traction and even rotation for the bale. Even bale rotation is vital to ensure the optimal film overlap for conservation and crop quality during storage. Square turntable: The DEUTZ-FAHR medium square bale turntable wrappers are equipped with two pairs of steel rollers with a ribbed profile. This profile ensures maximum bale traction, even bale rotation and proper film overlap. Two large bale support rollers provide additional stability and guidance. Round bales can also be wrapped with these wrappers. Film cutters: Once the desired number of film layers have been applied, the film is then held firmly and cut. On the turntable wrapper models, a spring-loaded or hydraulic high grip film cutter holds and cuts the film automatically without the need for extra controls. On DEUTZ-FAHR satellite wrappers, the well-known "scissor-type" cutters hold and cut the film. Due to its design, the film is caught across the full width. The film is held with a clamp, stretched into one solid string, and then cut before the bale is unloaded. The clamp firmly holds the film ready for the next bale. Pre-stretchers: The standard pre-stretchers which hold a 750 mm roll, are made of aluminum to avoid build-up of tack from the film. Both outer ends of the aluminium rollers are cone shaped to maintain the optimum width of the film and reduce the risk of film tear. The special ribbed profile of the aluminum rollers keeps air and water away from the film. The location of the pre-stretchers makes it very easy to change the film rolls. The standard pre-stretch of 70% is reached by a low-maintenance and low noise gear transmission. e-Twin Technology: Besides a standard single stretch, DEUTZ-FAHR introduces the all new WM series with patented* e -Twin system for excellent cost efficient fast wrapping. The innovative e -Twin technology enables wrapping via an unique combined pre-stretcher design with patented* film distribution to save 50% on wrapping time and further film savings. The conical pre-stretch rollers have been positioned in such a way that the two 750 mm film wraps with 2/3 overlap are glued together providing a double layer before they leave the pre-stretcher unit. UNIQUE ADVANTAGES OF E-TWIN TECHNOLOGY: - Save 50% wrapping time. - Further film saving achieved by increased pre stretch ratio. - Tighter wrapped bales increases the airtightness and so quality to feed. - Extreme tear resistance under all circumstances. - Available on manual, joystick and computer version. True wrapping intelligence – WM 4044: DEUTZ-FAHR introduces a true innovation in bale wrapping with the WM 4044. This versatile self-loading square- and round bale wrapper features a unique patented* AutoLoad function for nonstop fully automatic wrapping. The innovative AutoLoad function provides non-stop fully automatic loading, wrapping and unloading of square- and round bales without interference from the driver. AutoLoad detects approaching bales, automatically scans the length of the bale and sets the loading arms into pre-load position, resulting in accurate loading, wrapping and unloading of the bale on the go. This leads to increased overall capacity and creates a more ergonomic and stressless working environment during a long working day. Excellent wrapping - Intelliwrap: Greater management and control of the wrapping process can be achieved by our unique IntelliWrap. IntelliWrap uses sophisticated electronics and hydraulics to monitor the wrapping process and continuously controls the film overlap, allowing total flexibility. Depending on local circumstances, crop conditions and storage periods the amount of film layers (4, 5, 6, 7, 8, 9...) can simply be adjusted. An excellent distribution of the film around the bale and precise overlap of the film provides maximum efficiency and increased silage quality. Always in control: Depending on model and user preference, three different control system are available. On machines with manual control (M), the machine is controlled with cable levers. This system may also be complemented with a bale/wind counter and an automatic stop function. Among other functions, the version with joystick control (J) automatically steers bale discharge. The computer controlled version (C) features a control unit providing all the necessary information and is capable of performing the entire bale wrapping process automatically. The WM 4044 is ISOBUS compatible. ISOBUS compatible tractors will therefore not require a separate control box for the wrapper. Alternatively, the VT50 or CCI 200 monitor can be used with tractors that are not ISOBUS compatible. Operator settings, such as selecting pre-defined bale dimensions and switching from transport into field mode, are accessed via the monitor. Information, such as wrapping process overview and number of bales, is also provided.